More Information

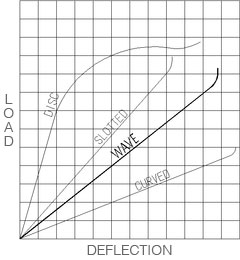

- Wave washers have more load build up and less deflection than a bowed washer.

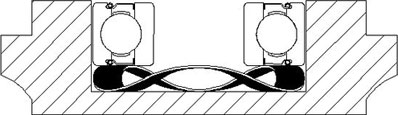

- Wave washers are usually used in thrust loading applications for small deflections, particularly where space is limited.

- Wave washers are used to provide a controlled amount of friction between two surfaces and to prevent rattles.

- The spring rate is approximately linear between 20% and 80% of available deflection.

Stock Materials

- Spring Steel: SAE 1074 / ASTM#A684, hardened to Rockwell C45-50.

- Stainless Steel: 301 / 302 Stainless Steel to ASTM#A177.

* These are materials we stock in various thicknesses. It does not mean we have finished inventory of all washers in each of these materials.

** Non stock alternate materials that are commonly run are Phosphor Bronze to ASTM#B103, Copper Alloy to UNS#C51000, and 17-7 Stainless Steel.

*** Customer specific materials different than those listed above are commonly run.

Finishes

- Steel: Provided Plain Finish. Wave washers can be provided with a mechanical zinc plating processed in house which eliminates hydrogen embrittlement. A wide range of additional coatings are available: zinc electroplating, phosphate coatings, black oxide, etc.

- Stainless Steel: provided plain finish or passivated.

- Phosphor Bronze: provided plain finish.