More Information

- Inexpensive, efficient, permanent method of closing/sealing manufactured holes in castings and other processes.

- Hubbard (Welch Type) Expansion plugs are perfect for limited space (depth) hole closure applications.

- Less expensive than cupped style plugs.

- Require a counter bore for installation.

- We have the widest range of sizes available anywhere – from 1/8” diameter up to 5-3/4” diameter.

Expansion plugs with a ground edge are available for applications requiring an exceptional degree of holding power or leak resistance. We are the original patent holder and manufacturer of the Welch Expansion Plug since 1913.

Stock Materials

- Steel: SAE1008/1010 low carbon steel: ASTM#A109 or A569 depending on gage.

- Aluminum:> 1100H14 to ASTM#B209.

- Brass: ASTM#B36.

- Stainless Steel: ASTM#A313

* These are materials we stock in various thicknesses. It does not mean we have finished inventory of all plugs in each of these materials.

** Customer specific materials different than those listed above are commonly run.

Finishes

- Steel: provided plain finish with a light oil. Expansion plugs can be provided with a wide range of coatings: mechanical zinc (processed in house), electro-zinc, black oxide.

- Aluminum: provided plain finish. Aluminum plugs are washed in a light mineral spirit in order to remove any solvents or residue.

- Stainless Steel: Provided plain finish. Stainless Steel plugs are washed in a light mineral spirit in order to remove any solvents or residue. Stainless plugs can be passivated.

- Brass: provided plain finish. Brass plugs are washed in a light mineral spirit in order to remove any solvents or residue.

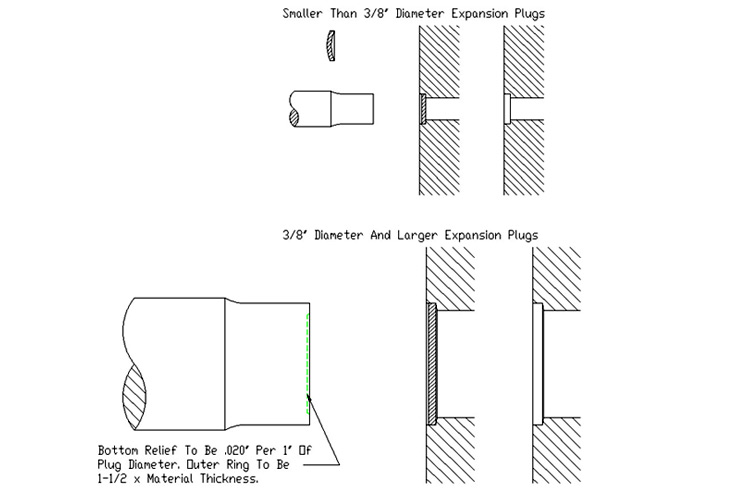

“d” Hole = Plug upper limit +.002”, more clearance may be needed for plugs over 2.5”.

Depth = 1-1/2 to 2 material thicknesses (1 material thickness minimum).

Shoulder = 1 material thickness

- The counter bore should be of a diameter that will take the plug without forcing, no larger. Typically this means .002” larger than the maximum plug diameter, although more clearance than .002” should be given to larger diameter plugs. If the plug is forced or press fit in the hole prior to expansion, the edge of the plug and the edge of the hole are apt to become marred, and leakage will occur.

- The counter bore should be round and free of tool chatter marks. 100 micro inches or smoother is a good finish guideline.

- The counter bore should be finished without any fillet. A fillet can prevent the proper seating of the plug. The counter boring tool should dwell long enough at the bottom of the counter bore to leave the bottom clean and smooth. The sharper the corner, the better the seal.

- The counter bore should be at least the depth of the material thickness of the plug to be installed.

- For the best condition, the width of the bottom of the counter bore should be approximately equal to the thickness of the plug to be used.

- For best results, the angle between the cylindrical sides and the bottom of the counter bore should be 95 to 97 degrees. This allows the plug to turn inside out slightly, and then spring back to an almost flat position – providing maximum sealing quality.

NOTE: The above hole configurations are for optimal sealing. Flat bottomed counter bores with varying shoulder widths are used for general sealing – applications with no liquid retention or pressure requirements.

DIN 470

The outside diameter (d) and spherical radius (r) of our metric plugs conforms to DIN 470 with no exceptions.

We offer many stock thicknesses and grades of material for each of these diameters – these stock grades and thicknesses do not always conform exactly to DIN 470.

The stock material grades we offer are listed under the “More Information” tab on this catalog page.

The stock material thicknesses that relate to each of these materials can be found by going through the RFQ process for a particular diameter of plug.

For quick reference, below is a table listing DIN 470 material thicknesses as well as the Hubbard Spring stock thicknesses for steel only:

| Diameter (d) | Spherical Radius (r) | DIN470 Material Thickness (s) | Hubbard Stock Steel Thickness (s) |

| 3 | 3 | 0.8 | 0.64, 0.81 |

| 4 | 4 | 0.8 | 0.64, 0.81 |

| 5 | 6 | 0.8 | 0.64, 0.81 |

| 6 | 7 | 1.0 | 0.64, 0.81 |

| 8 | 9 | 1.0 | 0.81, 1.27, 1.57 |

| 10 | 12 | 1.6 | 0.81, 1.27, 1.57 |

| 12 | 16 | 1.6 | 0.81, 1.27, 1.57 |

| 14 | 19 | 1.6 | 0.81, 1.27, 1.57 |

| 16 | 22 | 1.6 | 0.81, 1.27, 1.57 |

| 18 | 25 | 1.6 | 0.81, 1.27, 1.57 |

| 20 | 28 | 1.6 | 0.81, 1.27, 1.57, 2.11 |

| 22 | 30 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 25 | 34 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 28 | 40 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 30 | 42 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 32 | 45 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 34 | 48 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 36 | 50 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 38 | 52 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 40 | 56 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 42 | 60 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 45 | 63 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 48 | 68 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 50 | 70 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 52 | 75 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 56 | 80 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 60 | 85 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 63 | 90 | 2.0 | 0.81, 1.27, 1.57, 2.11 |

| 80 | 112 | 3.0 | 1.27, 1.57, 2.11, 3.40 |

| 100 | 140 | 3.0 | 1.27, 1.57, 2.11, 3.40 |

| 125 | 180 | 3.0 | 1.27, 1.57, 2.11, 3.40 |

We can quote metric plugs with thicknesses that conform to DIN470 – however if you can work with our stock material the piece price will be more economical, especially for small and medium volume orders.